Design Objectives & Methodology

This freshman-year engineering project challenged students to design and manufacture a miniature windmill with multiple competing objectives that required careful optimization and engineering trade-offs.

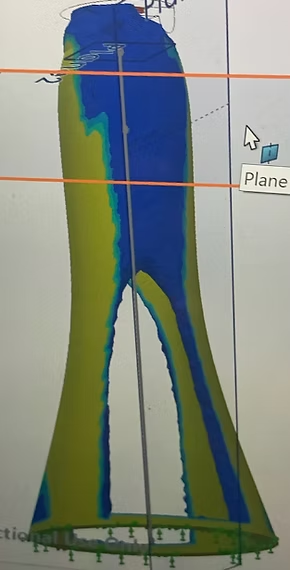

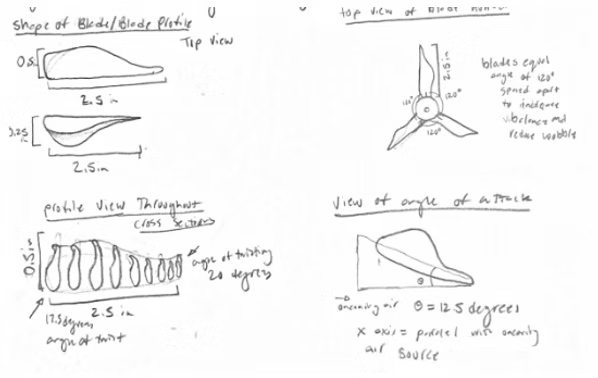

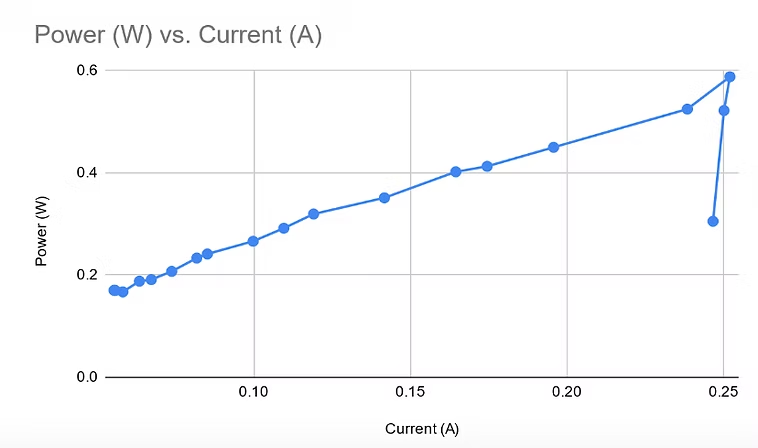

Power Maximization

Optimize blade geometry and configuration for maximum energy conversion efficiency

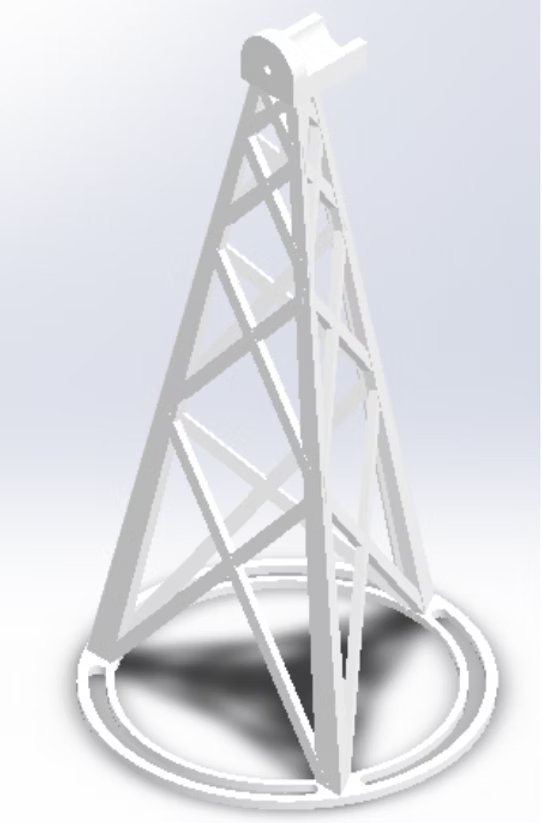

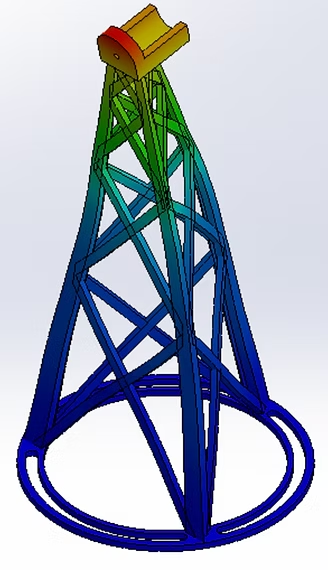

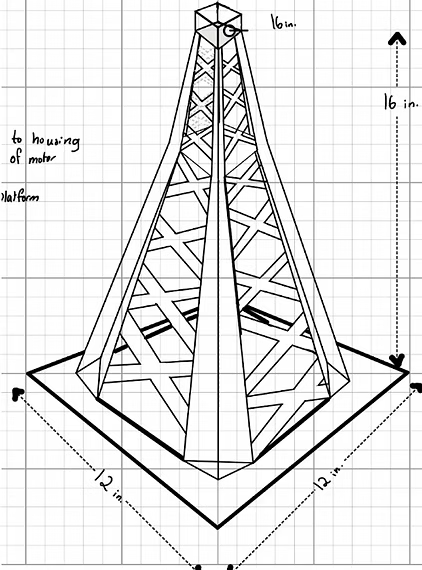

Structural Optimization

Maximize stiffness while minimizing weight through topology optimization

Creative Design

Innovative approaches to traditional windmill architecture and functionality

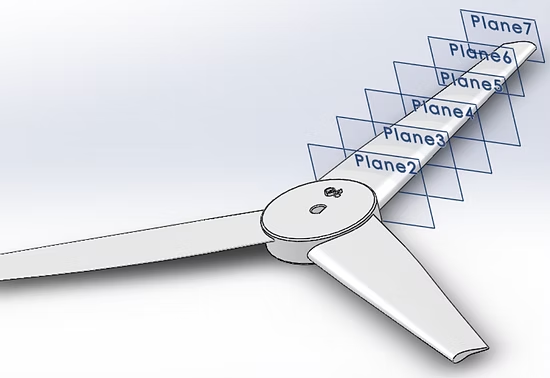

Manufacturing

Design for 3D printing constraints and assembly requirements