Product Vision & Execution Strategy

Goal: Define a compact, portable detector that combines radiation-adjacent learning with multi-sensor environmental monitoring in a single build, using accessible components and clear success criteria.

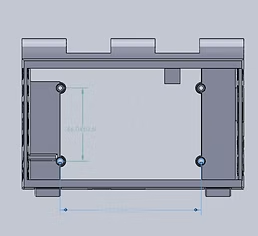

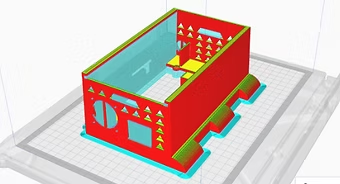

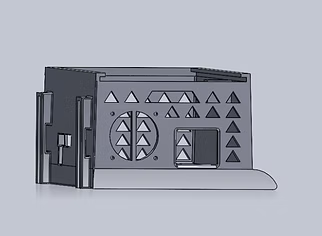

Approach: Framed the work as two streams—software/data (programming, sensor interfaces, statistics) and mechanical (case CAD and manufacturing). Sequenced the roadmap: research → modeling/validation → hardware feasibility → software DAQ → case design & manufacturing.

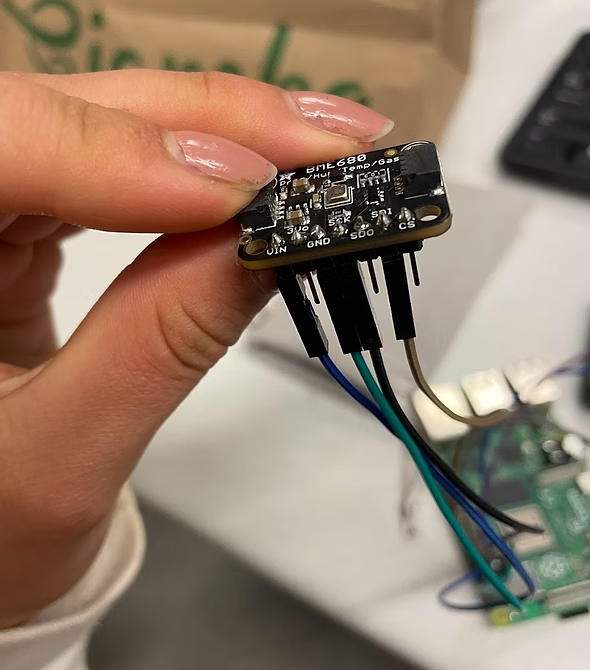

Outcome: A working prototype integrating PM2.5, BME680 environmental sensing, GPS, and a 3D-printed case with a laser-cut top. Decisions were documented, trade-offs were explicit, and each iteration tied back to requirements.

.png)