Product Vision & Execution Strategy

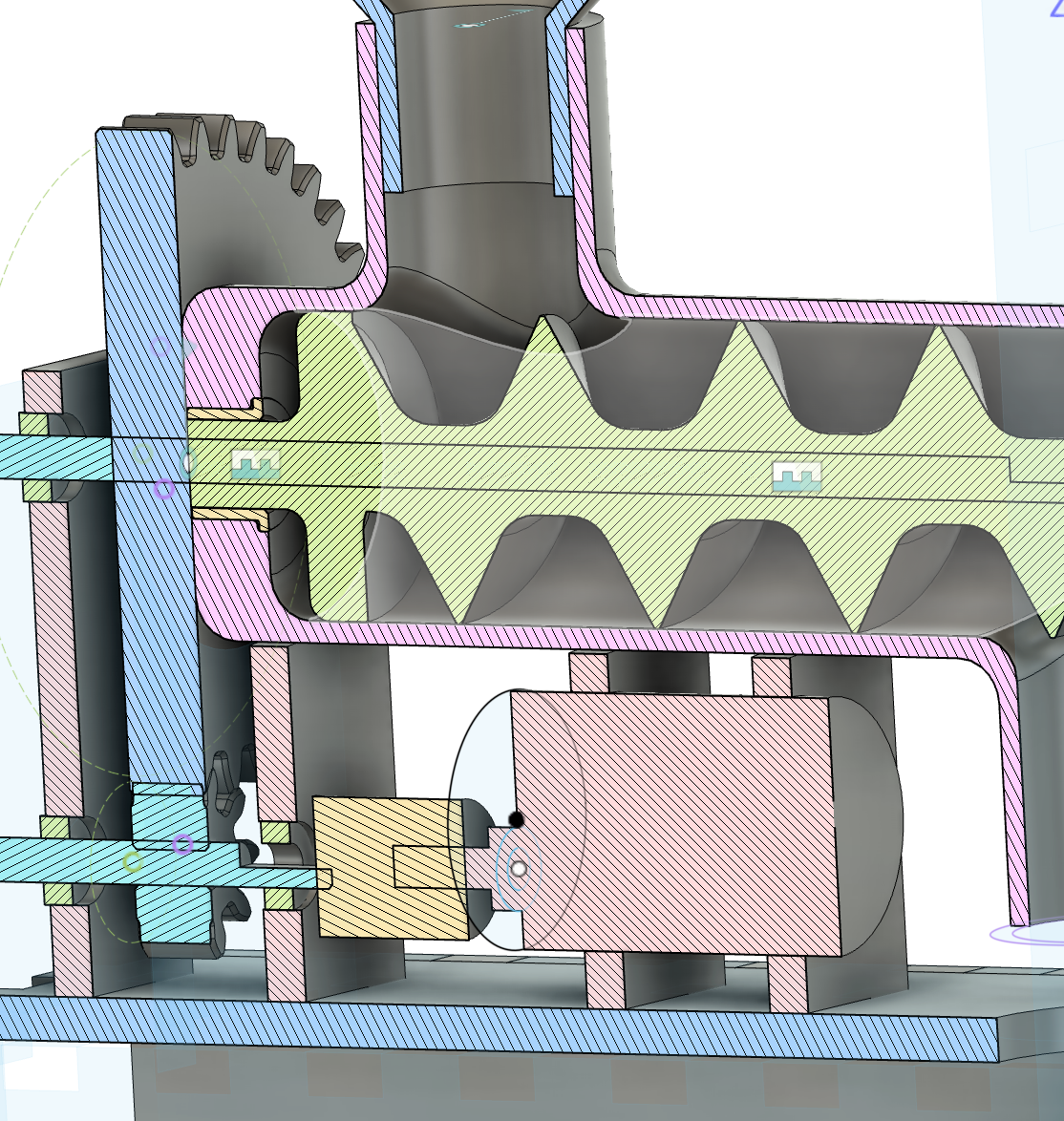

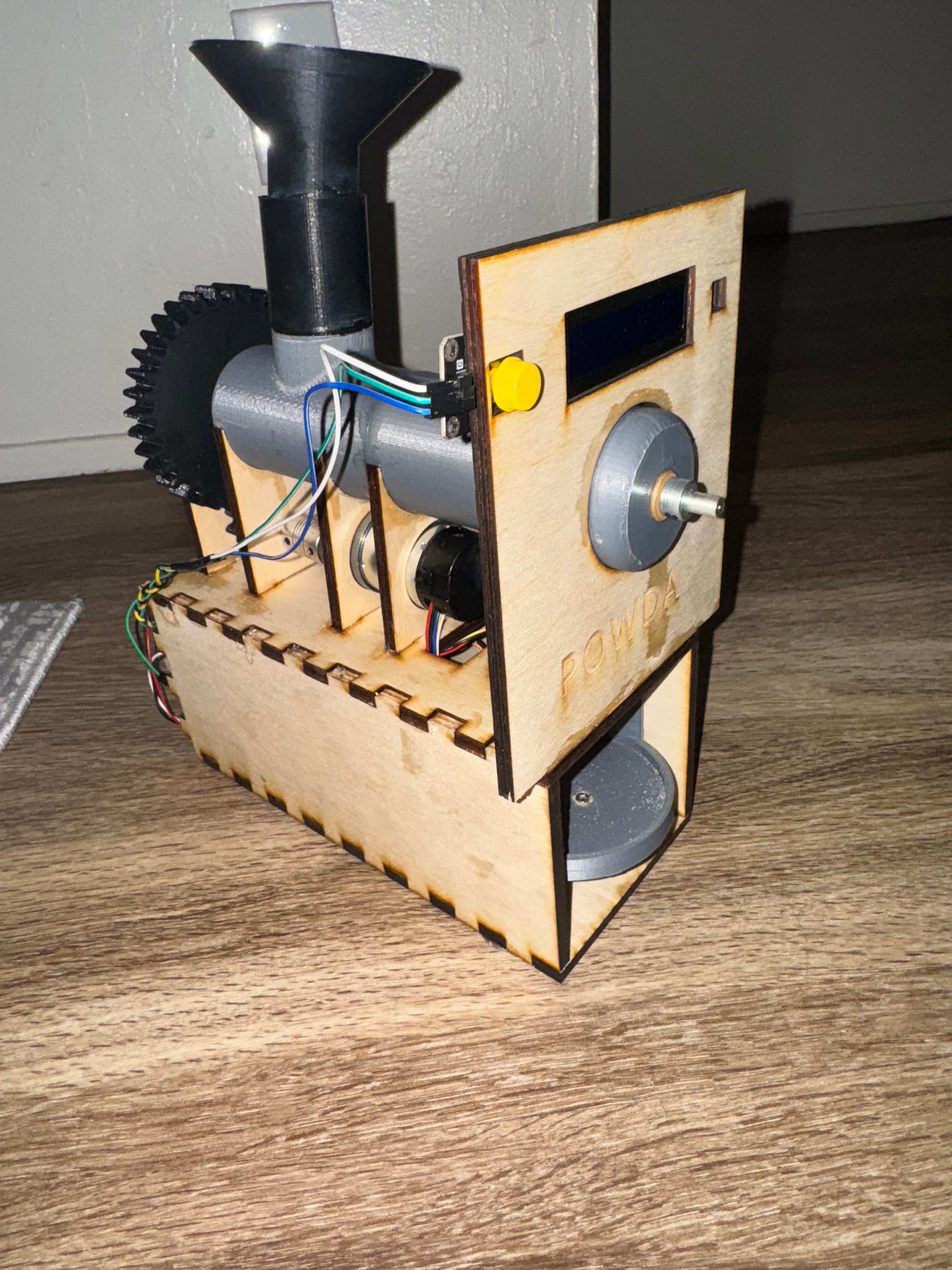

Goal: Define a precise, automated dispenser that eliminates the mess and inconsistency of manual scooping while maintaining simplicity and reliability for fitness enthusiasts and health-conscious users.

Outcome: A functional MVP that won "Best Entrepreneurship Award" for execution and market validation, delivering ±1g accuracy with 98% success rate and 3-second average cycle time.

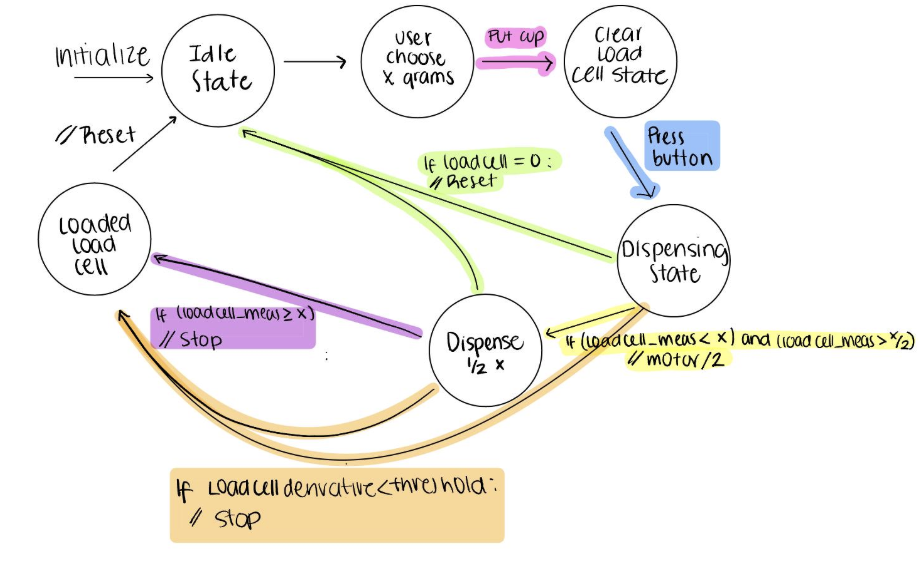

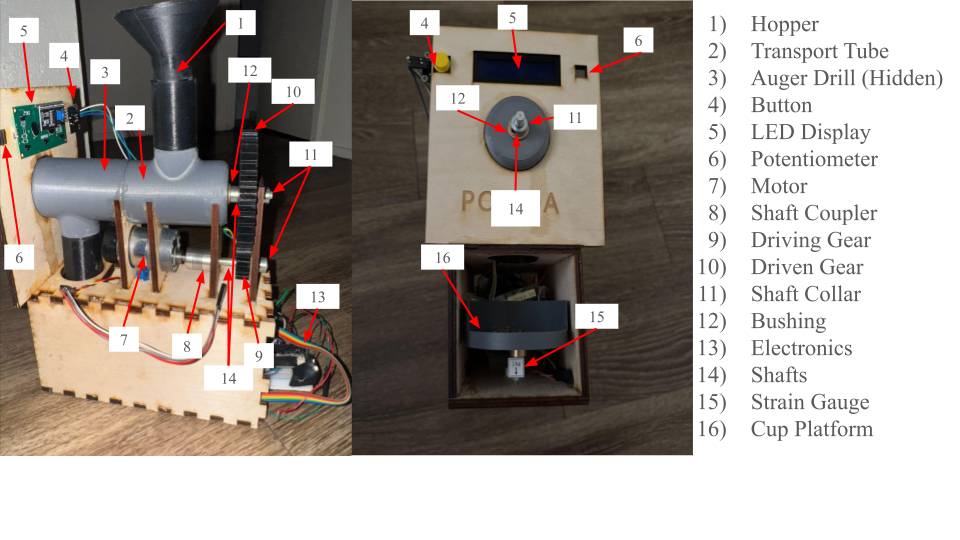

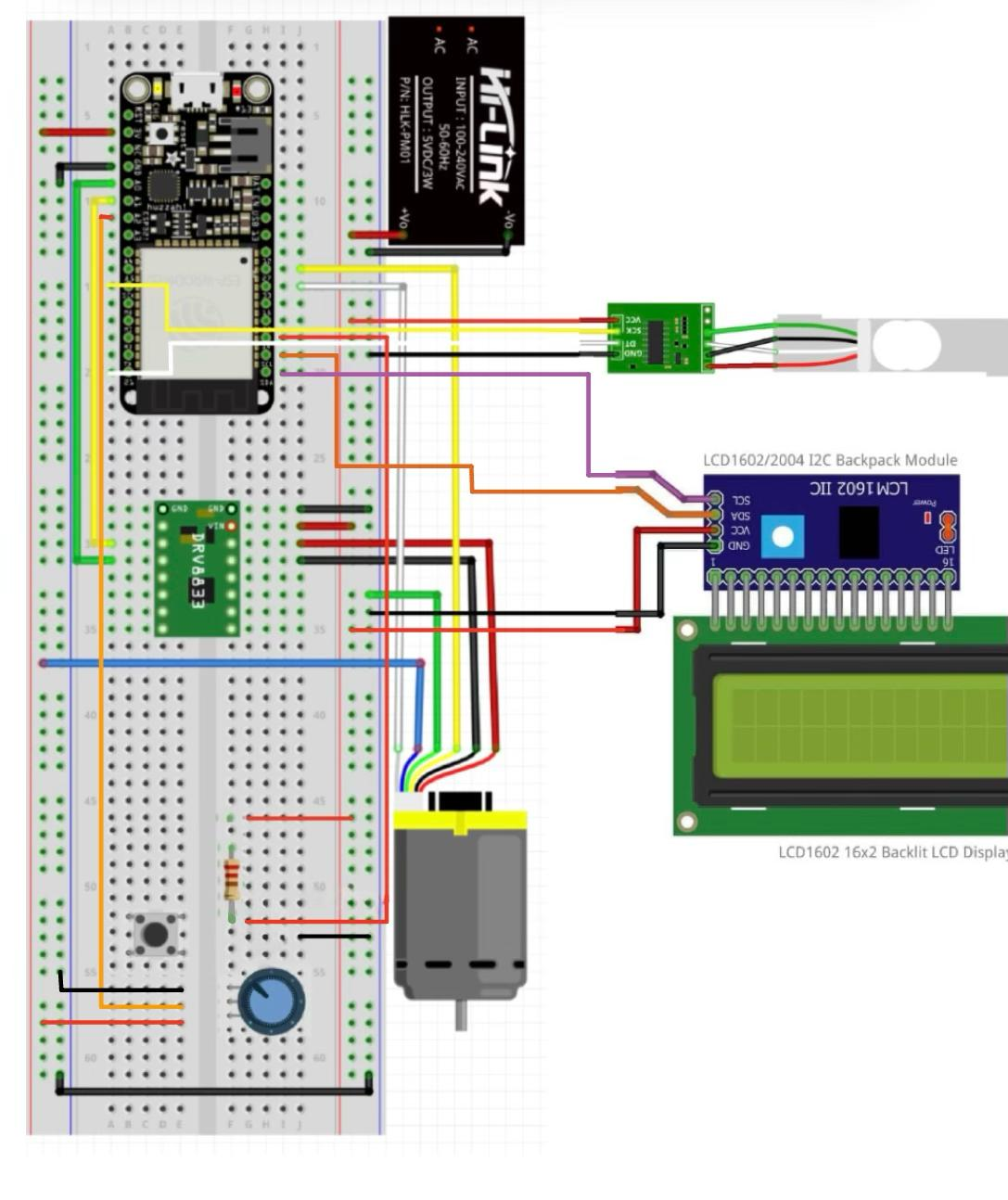

My Role: Product lead and systems engineer across the full development cycle. Performing user research and PRD development. Concept selection using weighted decision matrix. Mechanical design: transmission, bearings, and alignment systems. Embedded software: state machine, PWM control, interrupt handling. Creating timelines and iterative improvements based on performance.

.png)

.png)

.png)